Delivery Conditions

1. Fundamental delivery conditions

The following conditions should be observed when sending general cargo shipments to Martin Braun KG:

1.1 Delivery note

- A delivery note should be attached to the merchandise

- The delivery note should contain our order number and material number

- The delivery note should contain the use-by date (UBD)

- The delivery note should indicate the batch(es)

1.2 Pallets / Transport containers

- At least one transport label pursuant to the GS1-128 standard (pallet label) per shipping unit (see Chapter 2). One label is attached to each front pursuant to the GS1 recommendation

- Only one batch per pallet where possible

- Mixed pallets should be marked as such and in a manner that clearly identifies how much of which batch is on the pallet. One pallet label is required per batch.

1.3 Use-by date (UBD)

- The UBD should be contained on the delivery note, all pallets and all labels.

1.4 Batch

- The vendor batch is imported by Martin Braun KG into the materials management system and may not contain more than 10 characters, due to technical restrictions.

1.5 Labelling of trade item

- Each trade item (applies to raw materials, commodities) should be marked with a GS1-128 barcode label (container label). For detailed information, see Chapter 3

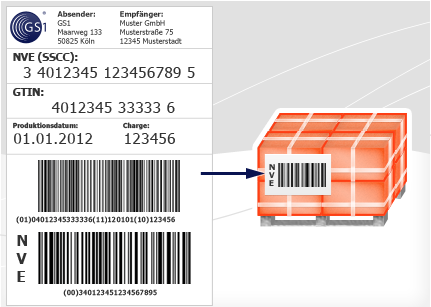

2. Appearance of GS1 transport label

All incoming shipping units should be marked with a transport label pursuant to the GS1-128 standard for the transmission of barcoded data content. Further information on the GS1-128 standard can be obtained from GS1 Germany (www.gs1-germany.de).

All information on labels should be clearly legible, and folds and tears should be avoided.

The manner in which Martin Braun requires the transport label to be realised is explained in the following Chapter 2.1.

Example: GS1 transport label

2.1 Transport label elements

The following label content is obligatory and must be printed in a clearly visible manner.

2.1.1 Plain text information

- Material number / customer part number / GTIN

- Material number (Martin Braun KG) or, alternatively, GTIN of the manufacturer

- Material identifier

- Supplier

- Order number

- Order number (Martin Braun KG)

- Batch

- Batch number (supplier)

- Delivery quantity

- Delivery quantity per shipping unit

- Specific material details in:

- KG : kilogramme

- PC : piece or CAR : carton

- M : metre

- Use-by date (UBD)

- Format DD-MM-YY

2.1.2 Information in GS1-128 barcode

- Material number / customer part number (241)

- Variable field length

- GTIN of trade item (01)

- Fixed field length (13 digits)

- Use-by date / UBD (15)

- Fixed field length (6 digits)

- Format YYMMDD

- Batch number (10)

- Variable field length, but maximum 10 digits specific to Martin Braun

- Order number (400)

- Variable field length

- Quantity per package / pallet

- In PC [piece] or CAR [carton] (30)

- Variable field length (maximum 8 digits, no decimal places)

- In M [metre] (311x)

- Fixed field length (6 digits, of these x decimal places)

- In KG [kilogramme] (310x)

- Fixed field length (6 digits, of these x decimal places)

3. Appearance of container label

A container label should be applied to each trade item in a clearly visible manner without folds and creases.

The GS1-128 standard is used as a barcode type. Further information on the GS1-128 standard can be obtained from GS1 Germany (www.gs1-germany.de).

The encoded content on the container label should not contain any more application identifiers than illustrated in the following Chapter 3.1.

In addition, the barcode content illustrated below should not be divided among more than one barcode.

Martin Braun prefers encoding of the customer part number application identifier (241). Alternatively, the GTIN application identifier (01) is permissible.

The Purchasing Dept. at Martin Braun KG should in all cases be informed of the GTIN prior to the initial delivery.

3.1 Container label elements

The following label content is obligatory:

3.1.1 Plain text information beneath the barcode

- Material number / customer part number / GTIN

- Material number (Martin Braun KG) or, alternatively, GTIN of the manufacturer

- Batch

- Batch number (supplier)

- Use-by date (UBD)

- Format DD-MM-YY

3.1.2 Information in GS1-128 barcode

- Material number / customer part number (241)

- Variable field length

- or: GTIN of trade item (01)

- Fixed field length (13 digits)

- Use-by date / UBD (15)

- Fixed field length (6 digits)

- Format YYMMDD

- Batch number (10)

- Variable field length, but maximum 10 digits specific to Martin Braun

3.2 Container label examples

3.2.1 With AI (241) customer part number:

3.2.2 With AI (01) GTIN:

4. Technical information on GS1-128 barcodes

The following technical information is non-binding and makes no claims with regard to completeness or correctness. Binding information on the GS1-128 standard can be obtained from GS1 Germany (www.gs1-germany.de).

4.1 Code GS1-128

In addition to the company and article numbers, the GS1-128 barcode can store additional information such as the batch number or use-by date. This is made possible by the so-called application identifier. A variety of information can be strung together in this manner. The data identifier prefixing information always assigns this information unequivocally to a category (e.g. the article number or batch).

4.2 Application identifier (AI) and data field identifier (DI)

So-called application identifiers and data field identifiers are used in the GS1-128 barcode symbology. The application identifier (AI) standard contains predefined data elements in which 2 – 4 digit start characters (AI) define the following data field in terms of format and data content. Brackets mainly visible in the plain text line should not be encoded in the symbol! The brackets only emphasise that a data field identifier is involved.

4.3 Stringing data fields

Several data fields can, in principle, be strung together, provided the restrictions listed below are observed. When stringing data fields, it is important to ensure that data fields with a variable field length are ended with a function code 1 (FNC1) character. The exception is when the data field is the last one in the string. It is therefore always sensible to position data fields with a variable length at the end of a data string.

4.4 Plain text line

Each data identifier should be indicated with brackets in the plain text line. The brackets only appear in the plain text line and have no equivalent in the barcode.

4.5 GS1-128 barcode restrictions

Including the quiet zones (a minimum of 10 modules on the left and right), the physical length should not exceed 165 mm. A module is the narrowest element in the barcode, whereby a quiet zone should be at least 2.5mm to 12mm wide, depending on the magnification factor. The minimum barcode height is 27 mm / 32 mm for SSCE symbols / should not be less than 13 mm were space is limited.

Including the data identifiers, a maximum of 48 payload characters may be encoded. FNC1 characters, which are encoded as separators, should be counted as payload characters. Including all auxiliary characters and symbol test characters, a GS1-128 barcode symbol should not exceed 35 symbol characters.

4.6 Please observe the following when creating and applying barcodes

- Edges (problems: blurring, avoid fraying)

- Exact ratios between the bar width and intermediate spaces (inaccuracies lead to metric errors and make identification of merchandise difficult)

- Contrast between bars and spaces (optimum: black bars on white background)

- Excessively glossy paper reflects too much, with the result that the scanner cannot read the barcode

- Aged or yellowed thermal paper leads to poor contrast ratios

- Ambient warehouse conditions for labels (damp, tear strength)

- No nets, welds, edges, curves, etc. over or in the vicinity of the barcode

- Positioning on the merchandise (barcode part should be level)

5. Further information

Martin Braun KG only assumes responsibility for the specific requirements in these delivery conditions. GS1 Germany GmbH is responsible for the GS1-128 standard.

Prior checks of GS1-128 barcodes can also only be conducted at Martin Braun according to content criteria. In the case of technical and syntax examinations of barcodes, Martin Braun KG assumes no liability for later functionality. Checking of barcodes can only be realised with original labels.

In addition to documentation addressing the topic of the GS1-128 standard, GS1 Germany also provides a barcode inspection service.